Smarter Automation for Smarter Factories

At Mindtroniks Technologies, we help you unleash the full potential of industrial robotics—making your manufacturing smarter, faster, and more adaptable. Our robotics solutions are not just about machines; they’re about empowering your workforce, optimizing floor space, and increasing throughput without compromising on safety or precision.

Whether you’re looking to reduce manual labor, improve cycle times, or expand production capacity, our scalable robotic systems are engineered to integrate seamlessly with your production goals.

Our Robotic Capabilities Include

Palletizing Automation

Speed up end-of-line operations with robotic palletizers capable of handling varied product sizes and configurations.

Features: Smart stacking logic, integrated safety, and minimal footprint.

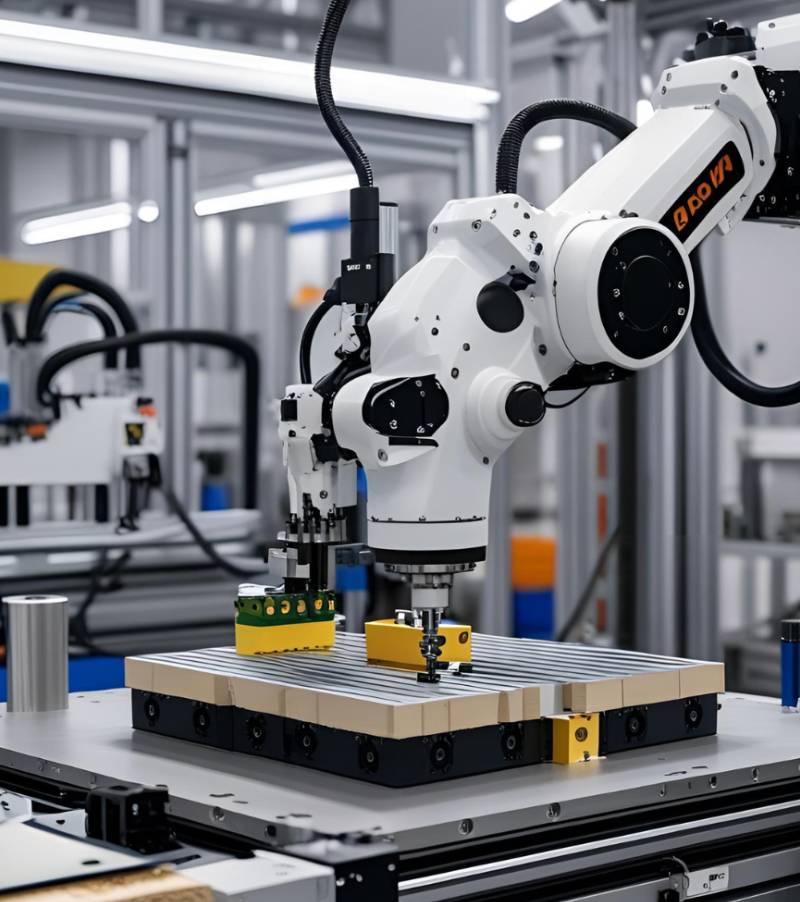

SCARA & Articulated Arms

Compact and high-speed arms solutions for pick-and-place, screwing, gluing, and light assembly.

Ideal for: Electronics, packaging, precision assembly, and repetitive tasks.

Packaging & Wrapping

Robots that handle packing, boxing, and sealing—ensuring uniformity, speed, and product safety during transport.

Applications: Cartoning, case-packing, bag loading, wrapping, and more.

Pick-and-Place Solutions

Automated robotics solutions for assembling components, ultra-fast sorting and handling repetitive tasks.

Uses: High-speed pick-and-place operations, sorting, and order picking.

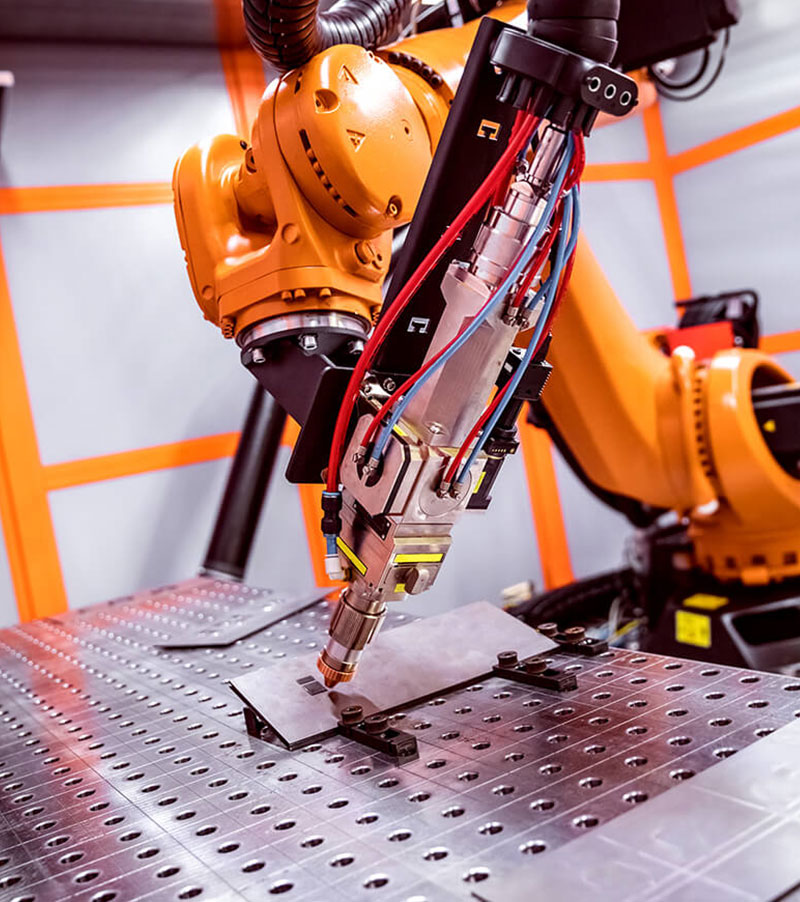

Robotic Welding Solutions

Precision-guided robotic welders for consistent weld quality across high-volume tasks, minimizing risks.

Applications: MIG, TIG, spot welding in automotive and metal fabrication.

Machine Tending & Material Handling

Autonomous robots for loading/unloading computer numerical controls or transfer materials across stations.

Outcome: Increased uptime, reduced human fatigue, and enhanced consistency.

What Sets Mindtroniks Apart?

- Custom End-of-Arm Tooling (EOAT): We design tools specific to your product’s weight, shape, and grip needs.

- Vision-Integrated Robotics: Enhance precision with AI-powered image processing and object detection.

- Seamless Integration: Our robotics work harmoniously with PLCs, conveyors, SCADA, and MES systems.

- Safety First: All systems comply with ISO/ANSI standards and are designed with fail-safes, light curtains, and emergency stops.

- Simulation & Layout Planning: We provide 3D layout simulation and cycle time estimation for all robotic setups.

Industries We Serve

- Automotive & Auto Components

- Electronics & PCB Assembly

- FMCG & Packaging

- Pharmaceuticals

- Metal & Welding Workshops

- Warehouse & Logistics Automation

Benefits of Mindtroniks Robotic Solutions

- Faster cycle times

- Repeatable accuracy

- Reduced operator fatigue

- Minimal downtime with predictive maintenance

- Smaller footprint and lower energy consumption

Ready to Automate?

Transform your production line into a flexible, intelligent, and high-performance system with Mindtroniks Robotics Solutions. From single-cell pick-and-place to fully automated robotic packaging lines—we deliver complete turnkey automation systems tailored to your factory.

Contact us today to schedule a site visit or discuss a robotics use-case that fits your plant.