Engineering Precision. Built Around Your Workflow

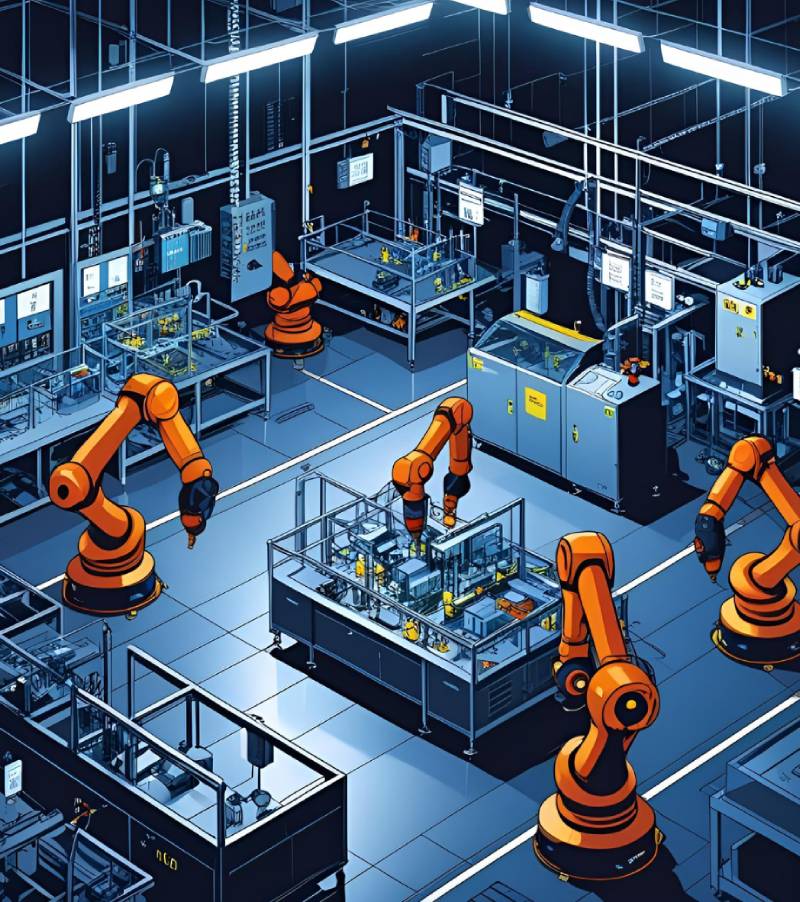

Mindtroniks specializes in developing custom-built automation systems that perfectly align with your unique production challenges. Whether you’re upgrading existing machinery, bridging disconnected systems, or building something completely new—our approach to custom engineering fuses mechanical precision with intelligent software integration.

Every production line is different, and our job is to design, integrate, and optimize systems that meet your specific throughput, quality, and safety requirements.

Our Engineering & Integration Capabilities

System Integration

We bring together robotics, PLCs, SCADA, MES, sensors, and legacy machines into a cohesive and intelligent production network.

Outcome: Real-time visibility, faster throughput, and fewer manual interventions.

Workflow Optimization

Analyze your production flow and reprogram machines and logic to remove bottlenecks and maximize performance.

Tools Used: Time-motion study, simulation modeling, and I/O mapping.

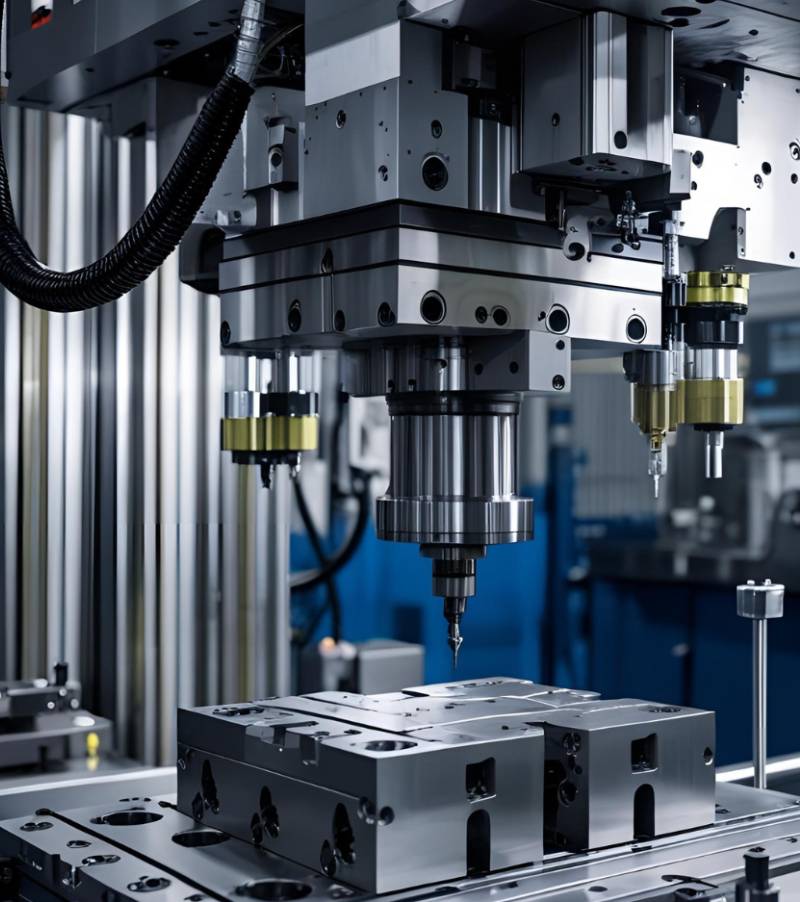

Custom Development

From scratch-built SPMs (Special Purpose Machines) to semi-automated jigs and fixtures, we design tailored solutions.

Applications: Cutting, pressing, drilling, assembling, dispensing, and more.

Custom Conveyors

Design and build application-specific conveyors, feeders, and elevators that fit the physical and logical flow of your plant.

Integrations: Robots, CNCs, packaging lines, and material handling equipment.

Modernization Solutions

Extend the life of your equipment with modern controls, sensors, and automation upgrades—without huge costs.

Benefits: Improved safety, better diagnostics, and optimized process.

Edge Computing

Enable smart decisions at the edge by integrating industrial IoT devices with cloud platforms, SCADA, MES, and systems.

Applications: Data loggers, predictive alerts, machine usage analytics, etc.

Why Choose Mindtroniks for Custom Engineering?

- Cross-Disciplinary Expertise: Mechanical, electrical, automation, and software teams working in sync.

- 3D Modeling & Simulation: See your custom solution before it hits the shop floor.

- Rapid Prototyping: We iterate fast with in-house design and fabrication.

- Retrofitting Know-how: We upgrade legacy machines without downtime nightmares.

- On-Site Commissioning: From wiring to programming, we install, test, and optimize on your floor.

Smarter Solutions. Smarter Production.

Let Mindtroniks turn your production goals into working systems. Whether you need to modify one machine or design an entire production cell, we’ll engineer the solution to fit your plant requirement.

Talk to our integration experts today and schedule a site visit or concept discussion.

Industries We Customize For

- Automotive & Component Manufacturers

- Consumer Electronics & Assemblers

- Pharma & Cosmetics

- Chemical & Lubricant Filling Lines

- FMCG & White Goods

- Custom OEM Projects

Future-Proof Your Factory with Mindtroniks

Gain full control of your assets, processes, and energy usage—in real time. From pilot projects to enterprise-wide digital transformation, Mindtroniks Technologies helps you implement IIoT and Smart Factory solutions that deliver measurable ROI, agility, and sustainability.

Talk to our IIoT consultants today and schedule a free audit or proof-of-concept deployment.