Robotics Solutions

ROBOTIC SOLUTIONS

Smarter Automation for Smarter Factories

At Mindtroniks Technologies, we help you unleash the full potential of industrial robotics—making your manufacturing smarter, faster, and more adaptable. Our robotics solutions are not just about machines; they’re about empowering your workforce, optimizing floor space, and increasing throughput without compromising on safety or precision.

Whether you’re looking to reduce manual labor, improve cycle times, or expand production capacity, our scalable robotic systems are engineered to integrate seamlessly with your production goals.

Our Robotic Capabilities Include

OUR ROBOTIC CAPABILITIES INCLUDE

Palletizing Automation

Speed up end-of-line operations with robotic palletizers capable of handling varied product sizes and configurations.

→ Features: Smart stacking logic, integrated safety, and minimal footprint.

SCARA & Articulated Arms

Compact and high-speed for pick-and-place, screwing, gluing, and light assembly.

→ Ideal for: Electronics, packaging, and precision assembly.

Packaging & Wrapping

Robots that handle packing, boxing, and sealing—ensuring uniformity, speed, and product safety during transport.

→ Applications: Cartoning, case-packing, and bag loading.

Pick-and-Place Systems

Integrated vision and robotics for ultra-fast sorting and object manipulation.

→ Uses: High-speed sorting, kitting, bin picking.

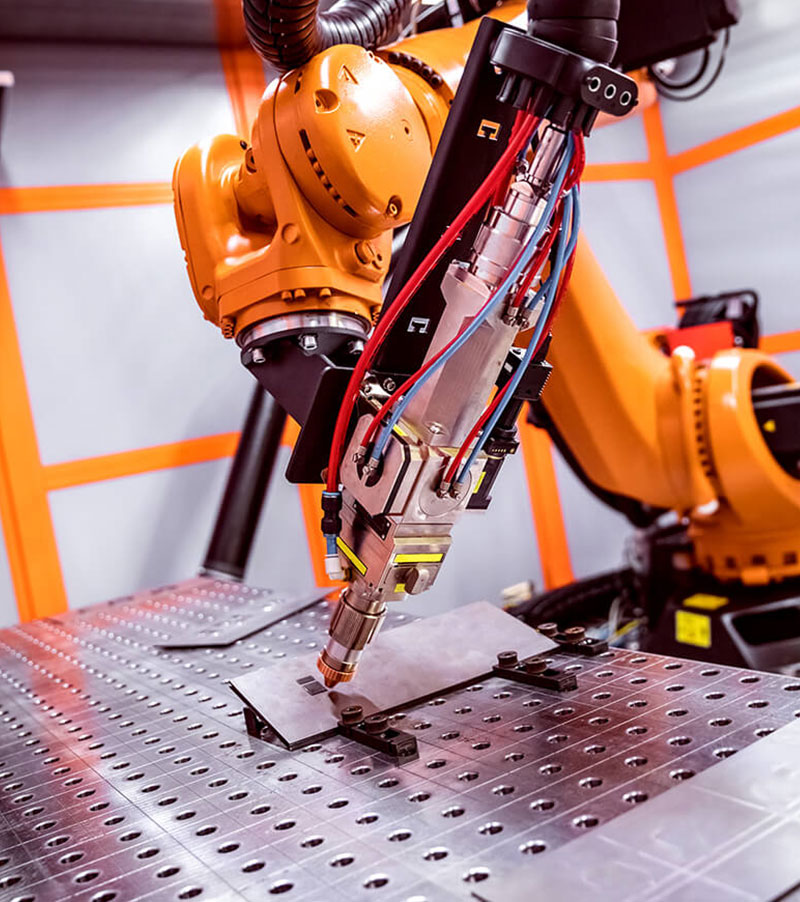

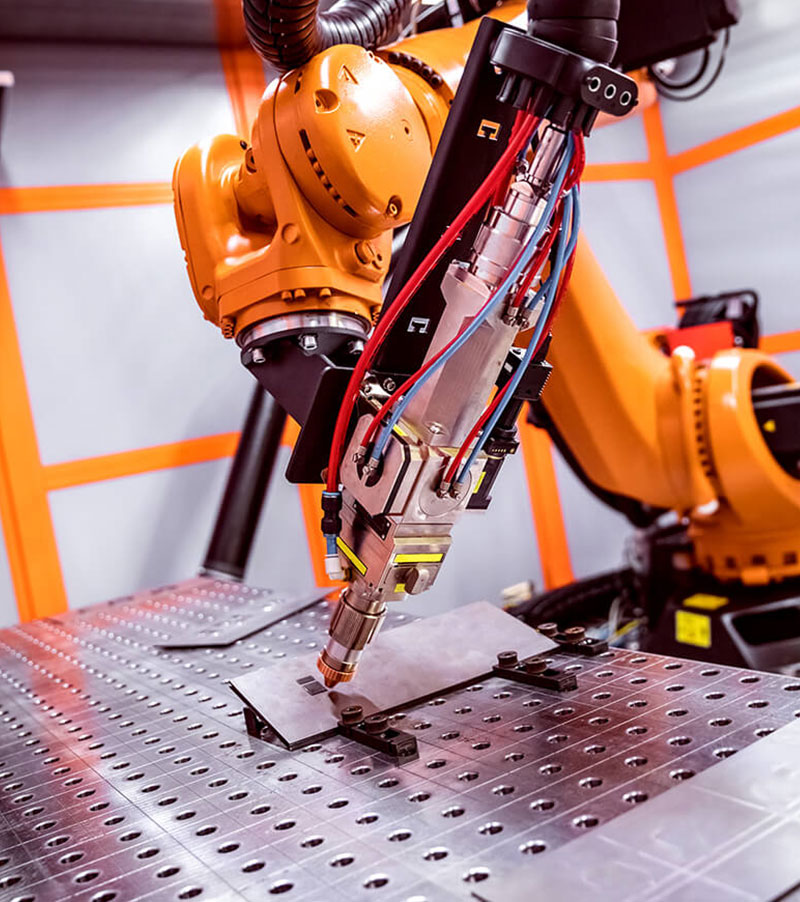

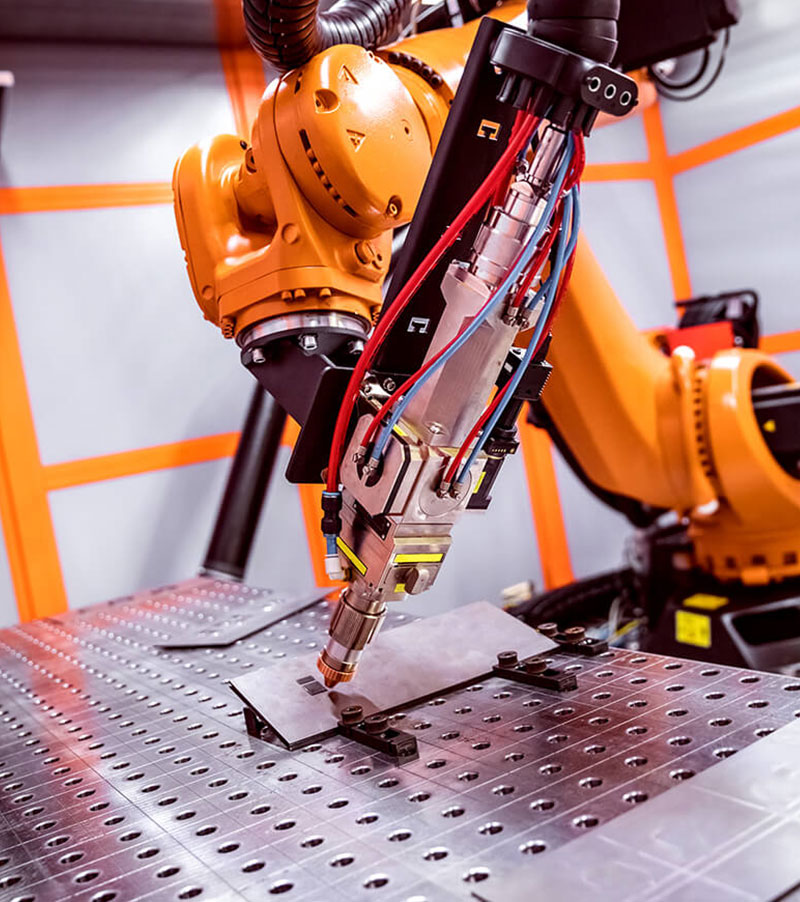

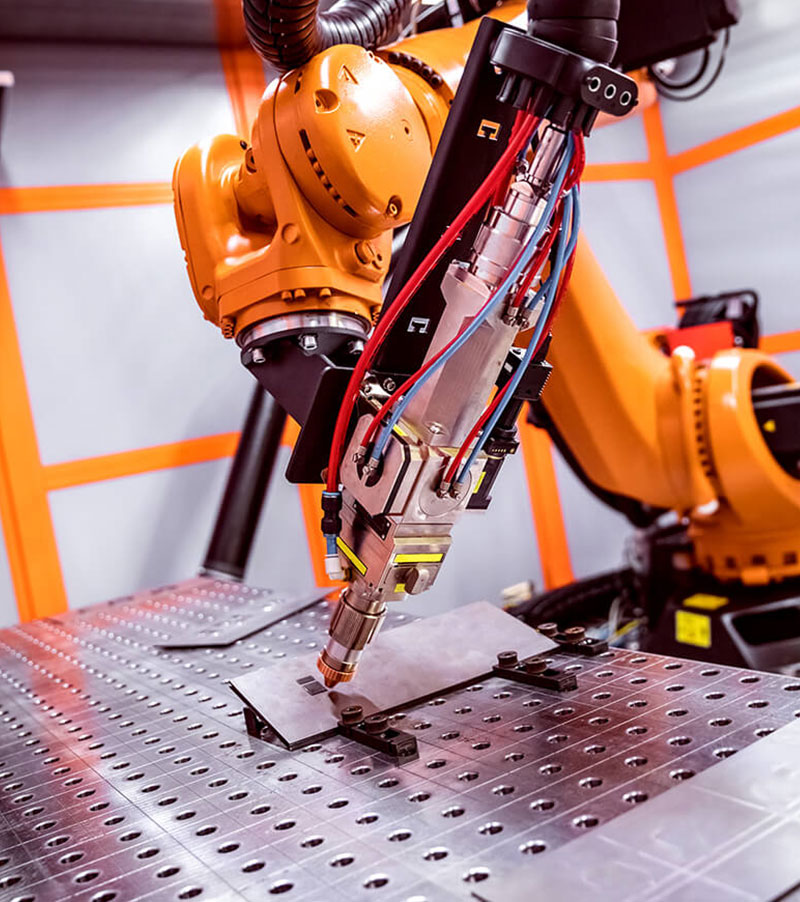

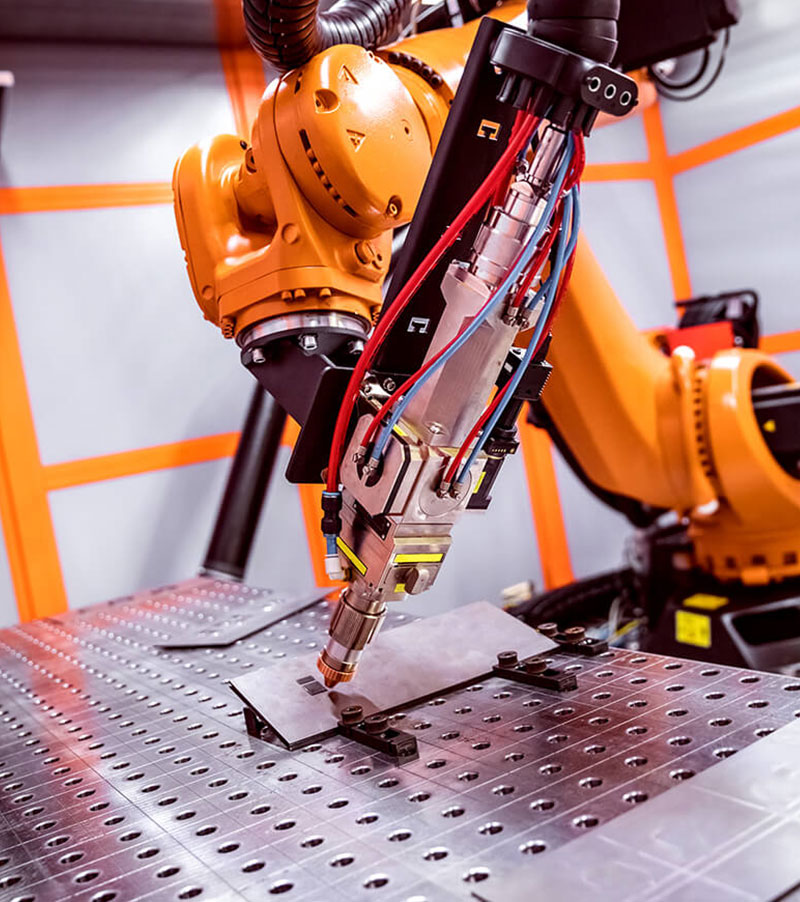

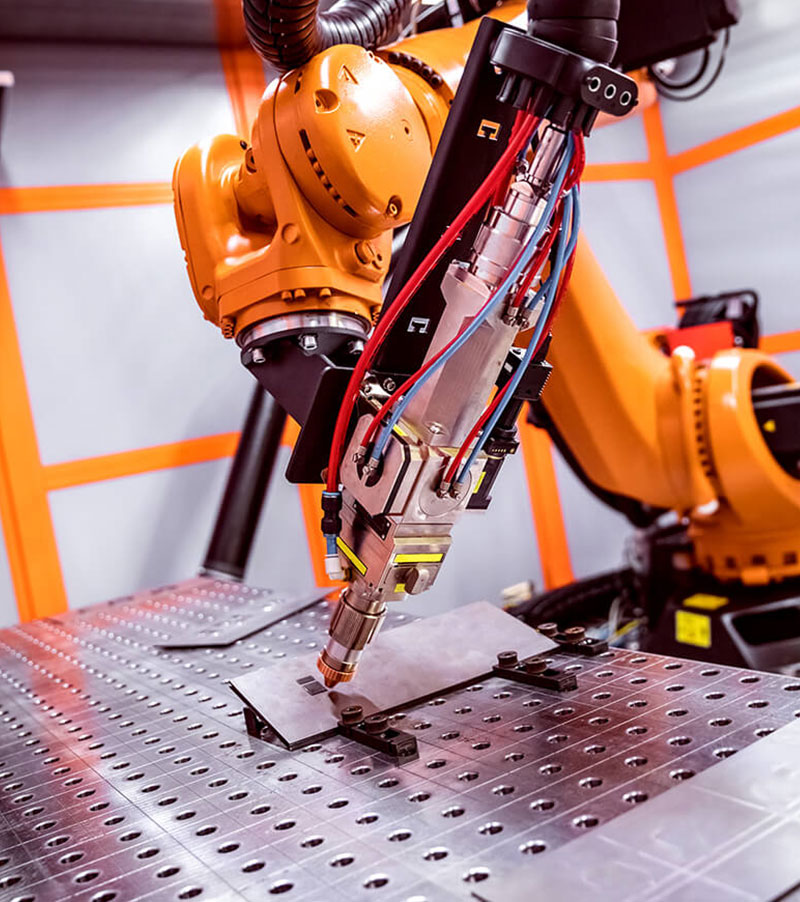

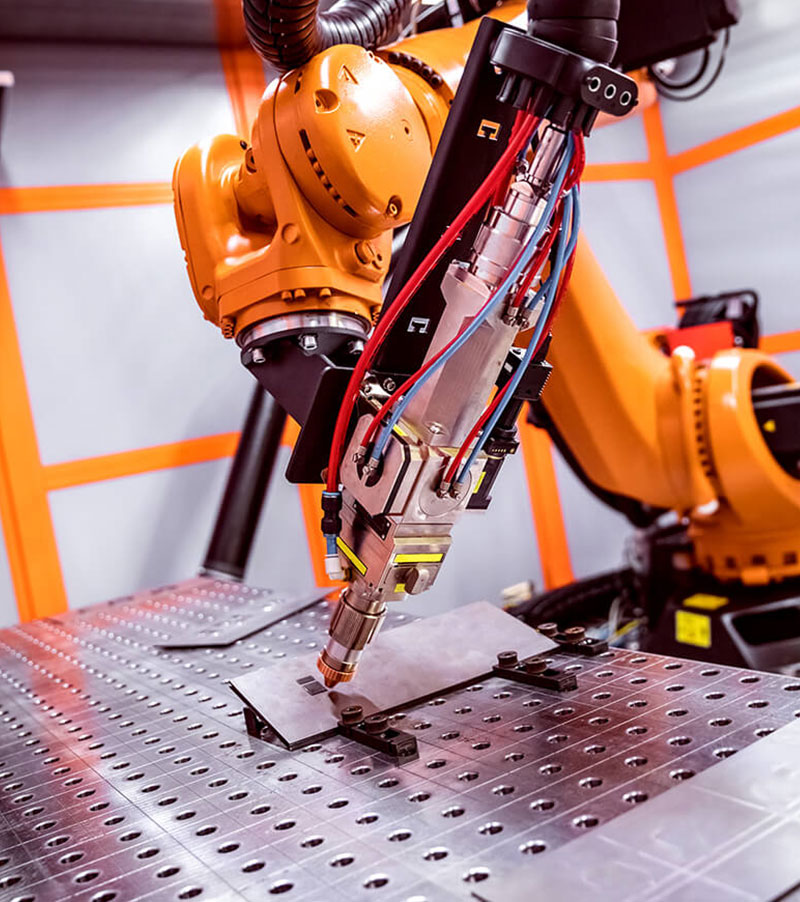

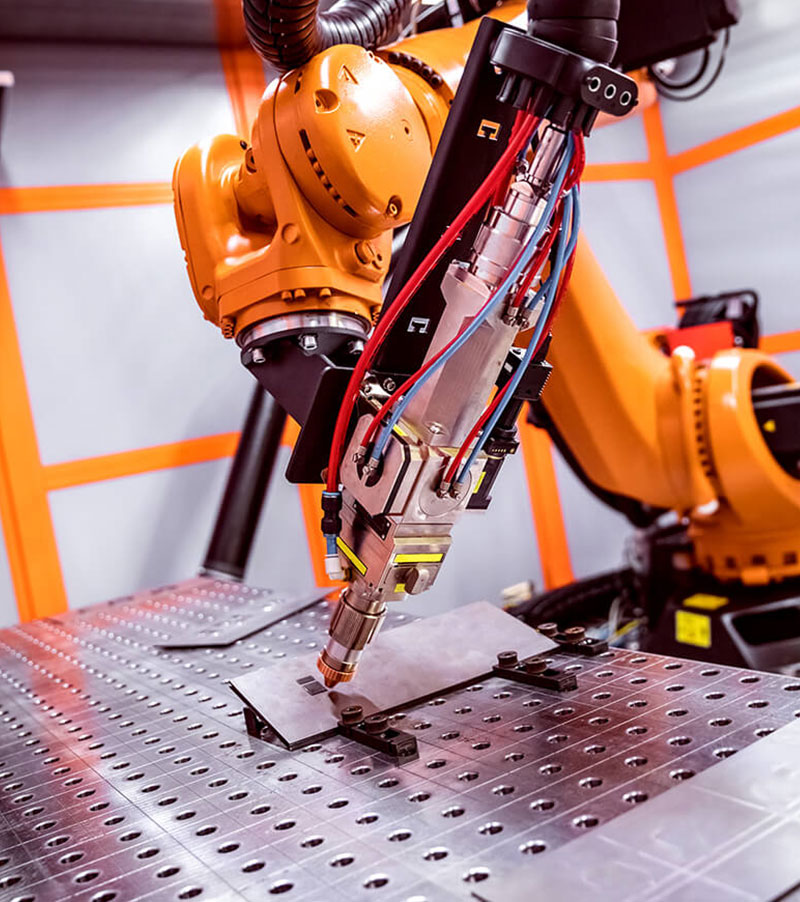

Robotic Welding

Precision-guided robotic welders for consistent weld quality across high-volume tasks, minimizing human exposure to heat and fumes.

→ Applications: MIG, TIG, spot welding in automotive and metal fabrication.

Machine Tending & Material Handling

Autonomous robots that load/unload CNCs or transfer materials across stations.

→ Outcome: Increased uptime and reduced human fatigue.

What Sets Mindtroniks Apart?

- Custom End-of-Arm Tooling (EOAT): We design tools specific to your product’s weight, shape, and grip needs.

- Vision-Integrated Robotics: Enhance precision with AI-powered image processing and object detection.

- Seamless Integration: Our robotics work harmoniously with PLCs, conveyors, SCADA, and MES systems.

- Safety First: All systems comply with ISO/ANSI standards and are designed with fail-safes, light curtains, and emergency stops.

- Simulation & Layout Planning: We provide 3D layout simulation and cycle time estimation for all robotic setups.

Industries We Serve

- Automotive & Auto Components

- Electronics & PCB Assembly

- FMCG & Packaging

- Pharmaceuticals

- Metal & Welding Workshops

- Warehouse & Logistics Automation

Benefits of Mindtroniks Robotic Solutions

- Faster cycle times

- Repeatable accuracy

- Reduced operator fatigue

- Minimal downtime with predictive maintenance

- Smaller footprint and lower energy consumption

Ready to Automate?

Transform your production line into a flexible, intelligent, and high-performance system with Mindtroniks Robotics Solutions. From single-cell pick-and-place to fully automated robotic packaging lines—we deliver complete turnkey automation systems tailored to your factory.

Contact us today to schedule a site visit or discuss a robotics use-case that fits your plant.

Conveyor Manufacturing

Engineered for Seamless Flow

Mindtroniks helps you design and manufacture high-performance conveyor systems that form the foundation of smart, efficient, and scalable production lines. Built for reliability and versatility, our conveyor solutions are tailored to meet the specific material handling needs of industries ranging from packaging and electronics to automotive and FMCG.

Whether you need a compact assembly line or a high-capacity transfer system, our in-house team delivers precision-engineered conveyor systems that improve uptime, reduce labor, and enhance safety.

Our Conveyor Range Includes

Belt Conveyors

Flexible and efficient systems ideal for transporting a wide variety of lightweight materials.

Features: Flat belt, cleated belt, incline options, and anti-slip surfaces.

Inclined Conveyors

Specialized belt conveyors designed for vertical or angled transport of loose or small parts.

Ideal for: Elevating goods, feeding machines, and reducing spillage on slopes.

Slat Conveyors

Built for heavy-duty or high-temperature applications with strong mechanical performance.

Ideal for: Metal stamping, machining processes, glass or hot parts handling.

Roller Conveyors

Efficient for moving cartons and bins, available as gravity-fed or motorized roller systems.

Best for: Packaging, warehousing, and order picking zones.

Chain Conveyors

Durable systems for transferring heavy loads or pallets across production lines.

Applications: Pallet transport, paint shops, assembly zones.

Gravity Conveyors

Economical solution for low-energy material movement with minimal maintenance needs.

Uses: Dispatch lines, loading/unloading docks, transfer tables.

Custom Conveyor Design & Integration

No two factories are the same. That’s why Mindtroniks offers custom-designed conveyor systems built around your plant layout, throughput requirements, and material type.

Our team conducts:

- On-site assessment & layout planning

- 3D CAD modeling of conveyor systems

- Integration with existing machinery & automation systems

- Seamless connectivity to PLCs, sensors, and robotics

Key Benefits

- Modular Construction – Scalable, easy to maintain, and upgradable.

- Heavy-Duty Materials – Built to withstand industrial loads and 24×7 operations.

- Precision Fabrication – Using laser cutting, CNC bending, and powder coating.

- Low Noise, High Efficiency – Quiet operation with energy-efficient drives.

- Safety Compliance – Fitted with emergency stops, guards, and safety rails.

Industries We Serve

- Packaging & FMCG

- Automotive Component Manufacturing

- Electronics Assembly & PCB

- Warehousing & E-commerce Fulfillment

- Bottling, Filling & Beverage Lines

- Paint Shops & Welding Units

Make Every Movement Count

Whether you’re moving bottles, boxes, pallets, or precision parts—Mindtroniks delivers conveyor systems engineered for performance and reliability. From single-line units to factory-wide conveyor networks, we ensure optimum flow, reduced bottlenecks, and better throughput.

Schedule a consultation with our design engineers and get a custom conveyor system built for your unique production needs.

Control Panels

Command Your Machinery with Confidence

At Mindtroniks, we engineer high-precision control panels that serve as the command centers for industrial automation. Designed with accuracy, safety, and scalability in mind, our panels are the result of decades of hands-on experience across diverse sectors—from automotive plants to process-driven industries.

Each panel is custom-configured to your machines, operational requirements, and industry regulations, ensuring seamless control, monitoring, and protection of your equipment.

Our Control Panel Offerings

PLC-Based Control Panels

Programmable Logic Controller (PLC) panels designed to manage complex automation workflows with high-speed logic, sequencing, and fault diagnostics.

→ Ideal for: Multi-station automation, SCADA integration, sequential operations.

Custom & Hybrid Panels

We design control panels tailored to unique processes, combining multiple control functions such as logic, safety, motion, and power control.

→ Examples: Filling line control cabinets, batching system panels, OEM-specific setups.

VFD Panels (Variable Frequency Drive)

Panels that enable dynamic motor speed control, improve energy efficiency, and reduce mechanical stress on systems.

→ Used in: Conveyors, pumps, compressors, HVAC systems.

Roller Conveyors

Efficient for moving cartons and bins, available as gravity-fed or motorized roller systems.

Best for: Packaging, warehousing, and order picking zones.

Motor Starter Panels

Reliable, rugged, and safe motor-starting solutions—including DOL, Star-Delta, Soft Starters—complete with overload protection and interlocking logic.

→ Applications: Pumps, blowers, compressors, agitators.

Gravity Conveyors

Economical solution for low-energy material movement with minimal maintenance needs.

Uses: Dispatch lines, loading/unloading docks, transfer tables.

Our Engineering Capabilities Include

- Wiring Diagrams & Layouts (EPLAN, AutoCAD)

- Panel Layout Optimization for space, heat dissipation, and serviceability

- Testing & QA: Megger, Hi-pot, load tests, interlock verification

- On-site Installation & Commissioning

-

Fieldbus & Industrial Protocol Integration (PROFIBUS, MODBUS, Ethernet/IP)

Industries We Serve

- Manufacturing & Assembly Lines

- Automotive & Component Suppliers

- Bottling & Packaging Plants

- Process Industries (Chemicals, Pharma)

- OEM Machine Builders

- Food & Beverage Automation

Optimize. Control. Scale.

Whether you’re launching a new process line, upgrading outdated panels, or integrating Industry 4.0 capabilities, Mindtroniks provides intelligent control panel systems that enable complete command over your production.

Connect with our automation engineers today for a free consultation or detailed technical proposal.

Liquid Filling Machines

Precision That Flows with Your Process

At Mindtroniks Technologies, we deliver high-performance liquid filling and packaging machines engineered to maximize accuracy, minimize product loss, and scale effortlessly with your production demands. Whether you’re bottling water, viscous creams, or chemical solutions, our systems are built for reliability, hygiene, and speed.

We offer complete end-to-end liquid packaging automation—from container rinsing to precise filling, capping, sealing, and labeling—customized to your product, container type, and output goals.

Our Equipment Portfolio Includes

Filling Machines

Designed for automatic and semi-automatic operations, our machines handle a wide range of viscosities—from water-thin liquids to heavy gels.

→ Features: No-drip nozzles, CIP/SIP compatibility, servo-controlled fill cycles

Rinsing & Bottle Prep Machines

Before filling begins, bottles go through automated internal rinsing or air blowing to ensure product purity and safety.

→ Used for: Glass, PET, HDPE, and aluminum bottles

Capping Machines

Reliable and adaptable machines for various cap types and closures—delivering tight seals and reducing manual labor.

→ Supports: Screw caps, ROPP caps, snap-on lids, flip tops, child-resistant caps

Sealing & Sleeving Solutions

Our heat shrink and induction sealing systems ensure leak-proof and tamper-evident packaging.

→ Applications: FMCG retail, pharmaceuticals, food-grade liquids

Sealing & Tamper-Evident Solutions

Heat shrink and induction sealing systems provide product integrity and tamper visibility.

→ Applications: Food & beverage, cosmetics, pharmaceuticals, FMCG.

Cup Elevators & Integrated Conveyance

Automated feeding and elevation systems streamline material flow and sync perfectly with upstream/downstream processes.

→ Used For: Cup filling lines, bottle transfer, and process automation.

Why Choose Our Liquid Filling Solutions?

- Customizable Configurations – From tabletop machines to fully automatic bottling lines

- High Fill Accuracy – Servo-driven control and sensor integration

- Low Waste Design – Anti-drip, zero product residue, and recyclable material handling

- Hygienic Construction – SS304/SS316L build, IP-rated panels, easy-to-clean design

- End-to-End Integration – Syncs with labeling, coding, SCADA, and batch tracking systems

Industries We Serve

- Beverages: Water, juices, alcohol, soft drinks

- Cosmetics & Personal Care: Lotions, serums, creams, shampoos

- Pharmaceuticals: Syrups, tonics, disinfectants

- Agrochemicals: Pesticides, plant nutrients, fertilizers

- Lubricants & Industrial Fluids

- Homecare & Hygiene Products

Scale Your Filling Line with Confidence

Whether you’re a startup entering the bottled product space or a high-volume manufacturer optimizing efficiency, Mindtroniks delivers proven liquid filling systems backed by decades of engineering experience. From container selection to complete line automation—we’re with you at every step.

Request a site visit or demo today, and discover how Mindtroniks can transform your bottling process.

IIoT & Smart Factory Solutions

Make Your Plant Smarter, Safer, and More Connected

In today’s competitive manufacturing landscape, connectivity is power. Mindtroniks enables factories to transition from traditional automation to intelligent, data-driven operations with our comprehensive Industrial Internet of Things (IIoT) and Smart Factory Solutions.

We help you connect your machines, extract real-time insights, and take action with precision—empowering your team to reduce downtime, improve asset performance, and confidently embrace Industry 4.0.

Our IIoT & Smart Factory Capabilities Include

Remote Monitoring & Control

Real-time visibility of machine performance and health from anywhere—via secure desktop or mobile access.

→ Monitor parameters, trigger alerts, perform remote diagnostics, and execute control commands.

SCADA & EMS Integration

Scalable Supervisory Control and Data Acquisition systems for centralized monitoring and energy optimization.

→ Track power usage, utilities, HVAC performance, and generate sustainability reports.

Custom Dashboards

Interactive, role-based dashboards to visualize KPIs, production metrics, energy usage, and maintenance alerts.

→ Drag-and-drop UI, filter-based views, integration with ERP/MES systems.

Cloud & Platform Integration

Seamlessly integrate with major cloud providers and on-premises servers.

→ Supported Platforms: AWS IoT, Microsoft Azure IoT Hub, Siemens MindSphere, private cloud.

Data Analytics & Predictive Maintenance

Analyze trends, machine behavior, and anomaly detection using historical and real-time data.

→ Outcomes: Predict failures, schedule maintenance, and reduce unplanned downtimes.

Cybersecurity & Access Control

Protect your industrial assets with multi-layered security protocols.

→ Includes: Encrypted communication, role-based access, secure VPNs, and device authentication.

Additional Capabilities

- Sensor & Device Integration – Connect PLCs, HMIs, edge devices, and legacy equipment

- AI-Enabled Process Intelligence – Use ML algorithms to optimize production paths and quality control

- Digital Twin Modeling – Simulate plant behavior before physical implementation

- Automated Report Generation – Custom reports for operations, energy, quality, and compliance

- MES/ERP Connectivity – Enable bi-directional flow of operational and business data

Industries We Serve

- Discrete Manufacturing

- FMCG & Packaging

- Automotive Components

- Heavy Engineering

- Pharmaceutical & Biotech

- Electronics & Device Assembly

Scale Your Filling Line with Confidence

Whether you’re a startup entering the bottled product space or a high-volume manufacturer optimizing efficiency, Mindtroniks delivers proven liquid filling systems backed by decades of engineering experience. From container selection to complete line automation—we’re with you at every step.

Request a site visit or demo today, and discover how Mindtroniks can transform your bottling process.

IIoT & Smart Factory Solutions

Make Your Plant Smarter, Safer, and More Connected

In today’s competitive manufacturing landscape, connectivity is power. Mindtroniks enables factories to transition from traditional automation to intelligent, data-driven operations with our comprehensive Industrial Internet of Things (IIoT) and Smart Factory Solutions.

We help you connect your machines, extract real-time insights, and take action with precision—empowering your team to reduce downtime, improve asset performance, and confidently embrace Industry 4.0.

Our IIoT & Smart Factory Capabilities Include

Remote Monitoring & Control

Real-time visibility of machine performance and health from anywhere—via secure desktop or mobile access.

→ Monitor parameters, trigger alerts, perform remote diagnostics, and execute control commands.

SCADA & EMS Integration

Scalable Supervisory Control and Data Acquisition systems for centralized monitoring and energy optimization.

→ Track power usage, utilities, HVAC performance, and generate sustainability reports.

Custom Dashboards

Interactive, role-based dashboards to visualize KPIs, production metrics, energy usage, and maintenance alerts.

→ Drag-and-drop UI, filter-based views, integration with ERP/MES systems.

Cloud & Platform Integration

Seamlessly integrate with major cloud providers and on-premises servers.

→ Supported Platforms: AWS IoT, Microsoft Azure IoT Hub, Siemens MindSphere, private cloud.

Data Analytics & Predictive Maintenance

Analyze trends, machine behavior, and anomaly detection using historical and real-time data.

→ Outcomes: Predict failures, schedule maintenance, and reduce unplanned downtimes.

Cybersecurity & Access Control

Protect your industrial assets with multi-layered security protocols.

→ Includes: Encrypted communication, role-based access, secure VPNs, and device authentication.

Additional Capabilities

- Sensor & Device Integration – Connect PLCs, HMIs, edge devices, and legacy equipment

- AI-Enabled Process Intelligence – Use ML algorithms to optimize production paths and quality control

- Digital Twin Modeling – Simulate plant behavior before physical implementation

- Automated Report Generation – Custom reports for operations, energy, quality, and compliance

- MES/ERP Connectivity – Enable bi-directional flow of operational and business data

Industries We Serve

- Discrete Manufacturing

- FMCG & Packaging

- Automotive Components

- Heavy Engineering

- Pharmaceutical & Biotech

- Electronics & Device Assembly

Scale Your Filling Line with Confidence

Whether you’re a startup entering the bottled product space or a high-volume manufacturer optimizing efficiency, Mindtroniks delivers proven liquid filling systems backed by decades of engineering experience. From container selection to complete line automation—we’re with you at every step.

Request a site visit or demo today, and discover how Mindtroniks can transform your bottling process.

IIoT & Smart Factory Solutions

Make Your Plant Smarter, Safer, and More Connected

In today’s competitive manufacturing landscape, connectivity is power. Mindtroniks enables factories to transition from traditional automation to intelligent, data-driven operations with our comprehensive Industrial Internet of Things (IIoT) and Smart Factory Solutions.

We help you connect your machines, extract real-time insights, and take action with precision—empowering your team to reduce downtime, improve asset performance, and confidently embrace Industry 4.0.

Our IIoT & Smart Factory Capabilities Include

Remote Monitoring & Control

Real-time visibility of machine performance and health from anywhere—via secure desktop or mobile access.

→ Monitor parameters, trigger alerts, perform remote diagnostics, and execute control commands.

SCADA & EMS Integration

Scalable Supervisory Control and Data Acquisition systems for centralized monitoring and energy optimization.

→ Track power usage, utilities, HVAC performance, and generate sustainability reports.

Custom Dashboards

Interactive, role-based dashboards to visualize KPIs, production metrics, energy usage, and maintenance alerts.

→ Drag-and-drop UI, filter-based views, integration with ERP/MES systems.

Cloud & Platform Integration

Seamlessly integrate with major cloud providers and on-premises servers.

→ Supported Platforms: AWS IoT, Microsoft Azure IoT Hub, Siemens MindSphere, private cloud.

Data Analytics & Predictive Maintenance

Analyze trends, machine behavior, and anomaly detection using historical and real-time data.

→ Outcomes: Predict failures, schedule maintenance, and reduce unplanned downtimes.

Cybersecurity & Access Control

Protect your industrial assets with multi-layered security protocols.

→ Includes: Encrypted communication, role-based access, secure VPNs, and device authentication.

Additional Capabilities

- Sensor & Device Integration – Connect PLCs, HMIs, edge devices, and legacy equipment

- AI-Enabled Process Intelligence – Use ML algorithms to optimize production paths and quality control

- Digital Twin Modeling – Simulate plant behavior before physical implementation

- Automated Report Generation – Custom reports for operations, energy, quality, and compliance

- MES/ERP Connectivity – Enable bi-directional flow of operational and business data

Industries We Serve

- Discrete Manufacturing

- FMCG & Packaging

- Automotive Components

- Heavy Engineering

- Pharmaceutical & Biotech

- Electronics & Device Assembly

Why Mindtroniks for Smart Factory Transformation?

- End-to-End Ownership – From device installation to analytics dashboard

- Platform-Agnostic Solutions – Compatible with leading PLCs, SCADA, and cloud providers

- Industrial-Grade Cybersecurity – Secure-by-design architecture

- Scalable Architecture – Start small, scale fast without rework

- Domain Expertise – Backed by automation engineers, data scientists, and IT specialists

Future-Proof Your Factory with Mindtroniks

Gain full control of your assets, processes, and energy usage—in real time. From pilot projects to enterprise-wide digital transformation, Mindtroniks Technologies helps you implement IIoT and Smart Factory solutions that deliver measurable ROI, agility, and sustainability.

Talk to our IIoT consultants today and schedule a free audit or proof-of-concept deployment.

Custom Engineering & Integration

Engineering Precision. Built Around Your Workflow

Mindtroniks specializes in developing custom-built automation systems that perfectly align with your unique production challenges. Whether you’re upgrading existing machinery, bridging disconnected systems, or building something completely new—our approach to custom engineering fuses mechanical precision with intelligent software integration.

Every production line is different, and our job is to design, integrate, and optimize systems that meet your specific throughput, quality, and safety requirements.

Our Engineering & Integration Capabilities

System Integration

We bring together robotics, PLCs, SCADA, MES, sensors, and legacy machines into a cohesive and intelligent production network.

→ Outcome: Real-time visibility, faster throughput, and fewer manual interventions.

Workflow Optimization & Line Balancing

We analyze your production flow and redesign or reprogram machines and logic to remove bottlenecks and maximize output per operator/hour.

→ Tools Used: Time-motion study, simulation modeling, and I/O mapping.

Custom Machinery Development

From scratch-built SPMs (Special Purpose Machines) to semi-automated jigs and fixtures, we design machinery tailored to specific product dimensions, materials, and operations.

→ Applications: Cutting, pressing, drilling, assembling, dispensing, and more.

Custom Conveyance Systems

We design and build application-specific conveyors, feeders, and elevators that fit the physical and logical flow of your plant.

→ Integrations: With robots, CNCs, packaging lines, and material handling equipment.

Retrofit & Machine Modernization

Extend the life of your equipment with modern controls, sensors, and automation upgrades—without full replacement costs.

→ Benefits: Improved safety, better diagnostics, and new operational capabilities.

Edge Computing & PLC-MES Gateways

Enable smart decisions at the edge by integrating industrial IoT devices with cloud platforms, SCADA, and MES.

→ Applications: Data loggers, predictive alerts, machine usage analytics, energy dashboards.

Why Choose Mindtroniks for Custom Engineering?

- Cross-Disciplinary Expertise: Mechanical, electrical, automation, and software teams working in sync.

- 3D Modeling & Simulation: See your custom solution before it hits the shop floor.

- Rapid Prototyping: We iterate fast with in-house design and fabrication.

- Retrofitting Know-how: We upgrade legacy machines without downtime nightmares.

- On-Site Commissioning: From wiring to programming, we install, test, and optimize on your floor.

Industries We Customize For

- Automotive & Component Manufacturers

- Consumer Electronics & Assemblers

- Pharma & Cosmetics

- Chemical & Lubricant Filling Lines

- FMCG & White Goods

- Custom OEM Projects

Smarter Solutions. Smarter Production.

Let Mindtroniks turn your production goals into working systems. Whether you need to modify one machine or design an entire production cell, we’ll engineer the solution to fit your plant requirement.

Talk to our integration experts today and schedule a site visit or concept discussion.

Future-Proof Your Factory with Mindtroniks

Gain full control of your assets, processes, and energy usage—in real time. From pilot projects to enterprise-wide digital transformation, Mindtroniks Technologies helps you implement IIoT and Smart Factory solutions that deliver measurable ROI, agility, and sustainability.

Talk to our IIoT consultants today and schedule a free audit or proof-of-concept deployment.